|

What are some of the tips and tricks when it comes to simplifying waterpark maintenance? WhiteWater’s Ray Sagasky has the answers...

Ray Sagasky | WhiteWater | 06 Mar 2024

Properly maintaining a waterslide can help significantly extend the life of the product Credit: WhiteWater Properly maintaining a waterslide can help significantly extend the life of the product Credit: WhiteWater

From Asia to the Middle East, from North America to South America - in the past few years, I have loved travelling the globe to refurbish water slides.

Having worked with so many waterpark operators, I have come across some common questions and misconceptions about water slide restoration. With preparations for the next water park season well underway for many, I’d like to take the opportunity to answer some of these.

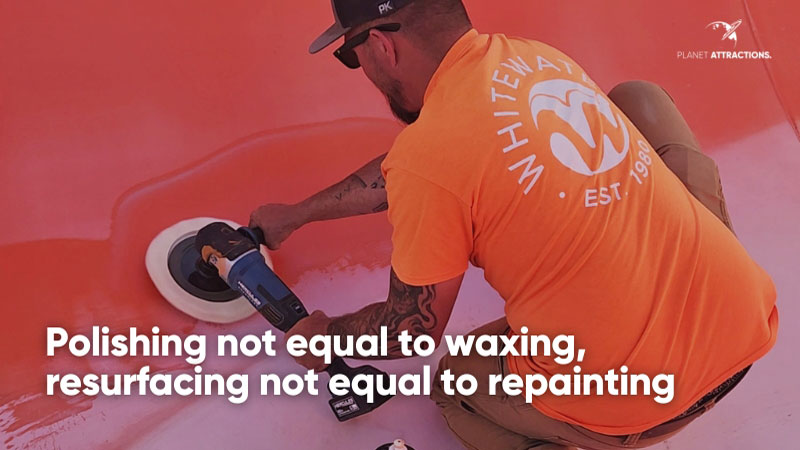

You might think these are just words. However, they are not interchangeable.

For example, polishing is what we do every couple of months to remove minor scratches and bring the slide back to its original shiny finish. Waxing is applying a protective layer; that should be done every couple of weeks.

Resurfacing is also a commonly misused word. This is the treatment that is used on the inside riding surface of the water slide to remedy excessive wear, primarily due to friction after years of usage. This process reapplies gel coat to the ride surface. It’s important to note that resurfacing is not the same as repainting, which is what we do on the exterior of the slide, mostly to remedy fading due to sunlight exposure, so environmental wear.

Referring to the inside surfaces of water slides, I have encountered many clients who think that they need to have the slides resurfaced. Oftentimes though, sanding and polishing would do the job.

How do you know? If there’s no fibreglass resin showing through, then sanding and polishing is enough. If it’s extremely worn and faded, then maybe it’s time for resurfacing. Contact the original equipment manufacturer (OEM) to take a look. They might also tell you that you don’t have to resurface the whole slide but rather, only a particular section.

So what are the pros and cons of resurfacing?

Pros: You’d be covering up friction wear, and you can extend the life of the slide path because you’ll be putting on a gel coat after resurfacing. Also, you’d need to resurface if you want to change the colour of your slide.

Cons: It’s more expensive to resurface compared to just sanding and polishing. And if you do resurface, you’ll never have the original glass-like, high-gloss finish again. You’ll have a textured finish, and it’ll be a bit harder to clean the calcium deposits on your water slide. That said, sometimes it is necessary to resurface, and prolonging the life of your investment is still a good thing.

In case operating parameters change after restoration work, the water slide would have to be re-commissioned by the OEM to ensure safe operations. Here are some situations where your slide would require re-commissioning:

• After resurfacing a water slide

• If the coefficient of friction on the slide path changes, for example, due to different coating or thickness of coating applied

• If the ride speed significantly changes after polishing

Absolutely not!

A water slide consists of big fibreglass sections, and these parts “move” with ride usage. They also contract and expand with temperature changes - consider your overnight lows and daytime highs.

WhiteWater’s water slide designs, laminate schedule, material selection, and fibreglass joints with caulking all play a part in allowing for this dynamic movement. If you put fibreglass over the seams, you could cause the slide parts to crack and eventually, cause injuries.

These are just a few points from my experience in waterpark maintenance. There’s much more to this topic, and I’m excited to be speaking in this IAAPA Education Webinar on March 13 called, “Water Park Maintenance: Tips to Avoid the Things We’ve Seen.” Join me and my fellow panellists, Nick Pawley from Qiddiya, Evan Forman from Palace Entertainment, and Franceen Gonzales from WhiteWater for a lively discussion covering practical insights, best practices, and mistakes to learn from.

Register here

Waterparks

|

|

Supplier Showcase 2025: The biggest attractions projects landing worldwide this year

|