|

As we enter the busiest time of the year for most waterpark operators, the team at WhiteWater has offered some tips to ensure the season runs smoothly

WhiteWater | 28 Jul 2022

Credit: WhiteWater Credit: WhiteWater

It’s late July. You’re sweating under the hot sun. You hear splashes and kids laughing as they go down a waterslide. You see more and more guests strutting through the gate. You’ve been working every day since late spring and you wouldn’t want to have it any other way.

We know. Being a waterpark operator in the middle of summer is hard work, and absolutely nobody is amused by downtime.

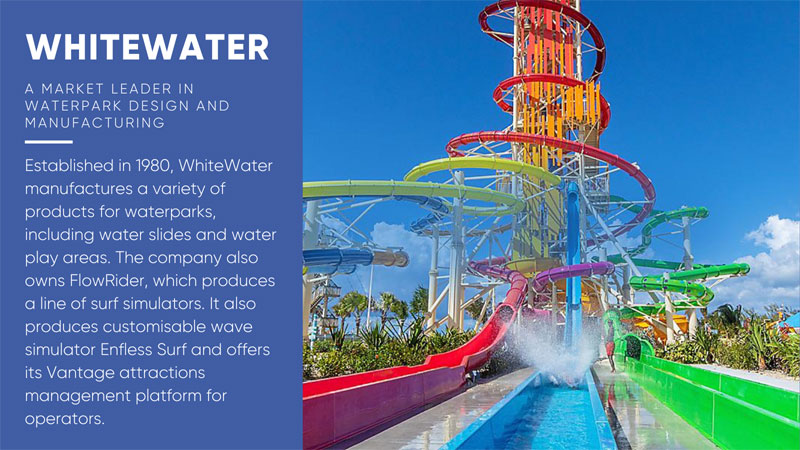

As the world’s biggest waterpark manufacturer, Whitewater has been helping its clients perform at their best for over 40 years - answering their questions, understanding their needs, and fulfilling requests in all shapes and sizes.

With so much knowledge, WhiteWater’s Performance Services Team would like to share some maintenance and support tips to get you through the busiest time of year.

“During operations is the time to know what you need,” says WhiteWater’s chief experience officer, Franceen Gonzales, who has decades of experience as an operator.

“Buy while money is coming in. Avoid buying when everyone else is in the spring because inventories may be low when you need parts right before opening.”

Think about parts that need to be replaced most often and order extras and spares earlier than later, especially when the world is still suffering post-pandemic supply chain woes. Keep a small inventory of parts on site to avoid ride downtime.

“I can’t emphasize enough that you need to have a copy of the equipment’s operation and maintenance manual handy,” says Kelly Wilkie, a performance specialist for Whitewater who has encountered a lot of different situations in her 16 years of working in after sales.

If you have an older slide and can’t find the manual, contact the manufacturer to request a copy. Smooth operations depend on you following this important document, especially when it comes to the next point.

“To keep attractions running safely, you need to check the water flow, water levels, and slide cleanliness every day before the water is turned on. If the water flow or water levels are not correct, or if there is excess calcium build-up, it’s not safe to operate,” said Whitewater’s Performance Service director, Harley Ensing.

Each attraction has its own list of daily checks in the O&M manual. Make sure you run the slides with test riders to ensure that they perform correctly and safely. If you have an AquaLoop, follow the daily procedure outlined to prevent issues. If you have a raft or inner tube ride, make sure the vehicles are properly inflated. If you have an AquaPlay unit, inspect the netting daily.

As well, check for signs of corrosion on slide supports, towers, and hardware. Performance Services project manager, Sara Homme, adds: “Have your maintenance team walk the slides on a set schedule looking for any chips, cracks, caulking issues, et cetera.”

Leaks might look small, but they add up, both financially and environmentally. That’s why it’s important to ensure that joints are caulked correctly and with the right caulking, so Sikaflex-1A or equivalent.

Here’s a pro tip from Performance Services Project Manager, Hanley Ishak, “3M’s Fast Cure 5200 is highly recommended if repairing mid-season.”

As employees come and go, always make sure your attendants and lifeguards are trained and are knowledgeable on what makes a water slide run safely as per the O&M manual.

Make sure they know when to shut the slide down if something is not right. Even better: “Cross train people on your team. This will help you manage better during low-staffing

times,” says Franceen.

Before you know it, autumn leaves will fall, and there will be other inspections and maintenance to perform to prepare for next year. At WhiteWater, we proudly stand behind our products. Whether before, during, or after the season, our Performance Services Team is here to help maximise the lifespan of your equipment and optimize the ride performance. Contact us for any parts and replacement, refurbishment, resurfacing, or inspection needs for your existing attractions.

Waterparks

|

|

Supplier Showcase 2025: The biggest attractions projects landing worldwide this year

|